Potato chips French Fries, A still bright future market

Potato chips show no sign of declining in popularity till today. The increasing young population, globally, disposable incomes and changing lifestyles are promoting higher consumption of potato chips. These chips are served as appetizers, side dish, or as snacks. Innovation or new product offering is considered as an opportunity for this market.

How to Make Crispy Fries? Automatic Potato Chips Making Manufacturing Process

01 Potato visual inspection When the potatoes arrive at the plant, the potatoes are examined for green edges andblemishes.

When the potatoes arrive at the plant, the potatoes are examined for green edges andblemishes.

02 Potato conveyers

The potatoes move along a potato lifter to potato peeling machine, there are a sediment design in

the feeding water sink. The sediment on potatoes is precipitated and discharged

through the sewage exit while conveyers.

However, potatoes need to be manual put into this water sink.

03 Potato peeling

Both batch potato chips production line and potato chips industry manufactures, potato peeling must be the necessary step.

Both batch potato chips production line and potato chips industry manufactures, potato peeling must be the necessary step.

Potato peeler machine ensures optimum peeling. The less peel is removed, the higher the yield of your process.

As the potato peeler machine manufacturers, our potato peeling machine has these features:

• Using brush rolls to finish the peeling of potato and separate shower for washing while screw blade carries potatoes forward.

• Small damage and more cleaning.

• Big capacity is suitable for industrial application.

Sometimes, two times operation for potato peeling is recommended, this depends on the final capacity and how fresh potato is. One is normally potato peeler, and second is a potato peeling machine with steam shower. This will be easy to remove thin skin from potatoes with minimum damage and maximum cleaning

04 potato sorting

After potato peeling process, hand picking will be done on a sorting table to select the defective potatoes.

And then up-to-standard potatoes will be conveyer to next process, chips or fries cutting and slicing.

05 Potato chips slicing

How to cut potatoes for French fries? How to cut waffle fries? How to make potato crisps?

How to cut potatoes for French fries? How to cut waffle fries? How to make potato crisps?

In this process, Potato chips slicing machine will cut the peeled potatoes into slices, chips, sticks, strips and shredded potatoes easily.

Straight blades produce regular chips while rippled blades produce ridged potato chips

Thickness of potato strips & slices are adjustable (from 1.5-10mm)

06 Potato chips washing

The slices fall into a cold-water air bubble washer that removes the starch released when

the potatoes are cut. Some manufacturers, who market their chips as natural, do not wash the starch off the potatoes.

07 Chips blanching

Sometimes, chips blanching process means color treatment.

Sometimes, chips blanching process means color treatment.

An accurate blanching time and correct temperature setting is the key for this process.

Potato Chips blanching machine has water temperature automatically controlled and blanching time adjustable freely.

After blanching process, potato chips or fries will have superior flavor, texture and color while active enzyme is restrained for easy reservation.

08 potato chips cooling

Potato chips and fries will have some extra temperature after blanching process, sometimes adhesion problem of chips and fries will happens. Cooling machine which uses the up and down air bubble will completely broke up the chips and fries while the temperature will drop immediately, at the same time, excessive blanching for chips and

fries will be avoid.

Potato chips cooling machine is the same to the chips washer.

09 Potato chips air blowing dehydration

Before the chips or fries are fried, it should be properly dried. This will raise the quality of the end result of the frying process, which results in a crispier.

Before the chips or fries are fried, it should be properly dried. This will raise the quality of the end result of the frying process, which results in a crispier.

Potato chips air blowing dehydration machine conveyer chips or fries with air blowing while chips turnover, the surface water will be removed completely and quickly, it is helpful for the frying process, not only saving frying time, but also having a crispier production.

10 Chips fries frying

How to make potato crisps? How to make fries?

In this process, fresh potato chips and fries will be fried with a continuously potato chips fries fryer.

• Continuously working, full automatic control, there is no any worry.

• Frying temperature can be controlled automatically

• Heating source is electricity; thermal efficiency is more than 95%

• Equipped with automatic oil filter, there is no carbonization in the oil and the oil will not turn black

• Potato chips French fries has bright color, good taste and improving product quality.

• Frying time in accordance with different recipe is easy to set up and automatic control during chips and fries frying process.

11. Fried Potato Chips De-fatting

Potato chips and French fires are crisper and tasty after de-oiling process, also too much fat has no benefits to health.

Potato chips and French fires are crisper and tasty after de-oiling process, also too much fat has no benefits to health.

Chips de-fatting machineis similar to potato chiops air blowing dehydration machine, a mesh belt pulls out the hot chips. As the chips move along the mesh conveyer belt, excess oil is drained off with a jet air blowing process and the chips begin to cool. They then move under an optical sorter that picks out any burnt slices and removes

12. Potato Chips Fries Flavouring

Potato chips that are to be flavoured pass through a drum potato chips fries flavoring machine which is filled with the desired powdered seasonings. to meet different customer demand for potato chips, hot chips, finger chips, fries, frites, potato wedges.

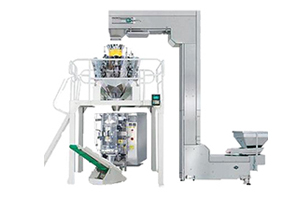

13. Potato Chips Packaging

The chips are conveyed to a chips automatic packaging machine with a scale. As the pre-set weight of chips is measured, a metal detector checks the chips once more for any foreign matter such as metal pieces that could have come with the potatoes or been picked up in the frying process.

The chips are conveyed to a chips automatic packaging machine with a scale. As the pre-set weight of chips is measured, a metal detector checks the chips once more for any foreign matter such as metal pieces that could have come with the potatoes or been picked up in the frying process.

Automatic Potato Chips Making Machine– For a Final Chips Capacity of 150Kg/h

| No. | Machine | Power | Dimension |

| 01 | Elevator | 0.37kw/380v/50Hz | 3200x1050x2500mm |

| 02 | Potato Peeling Machine | 2.75kw/380v/50Hz | 3050x800x1600mm |

| 03 | Potato Sorting Table | 0.37kw/380v/50Hz | 3500x740x1100mm |

| 04 | Elevator | 0.37kw/380v/50Hz | 1800x700x1600mm |

| 05 | Potato chips French Fries slicing Machine | 0.75kw/380v/50Hz | 745x590x1385mm |

| 06 | Air bubble Washing Machine | 1.87kw/380v/50Hz | 3000x1300x1400mm |

| 07 | Potato Chips Blanching Machine | 78.75kw/380v/50Hz | 5000x1070x1400mm |

| 08 | Potato Chips Cooling Machine | 1.87kw/380v/50Hz | 3000x1300x1400mm |

| 09 | Air-dehydration machine | 6kw/380v/50Hz | 4000x900x1700mm |

| 10 | Potato Chips Frying Machine | 130kw/380v/50Hz | 6000x1700x2250mm |

| 11 | Potato Chips de-oiling Machine | 6kw/380v/50Hz | 4000x900x1700mm |

| 12 | Potato Chips Sorting Table | 0.37kw/380v/50Hz | 4000x700x1255mm |

| 13 | Potato Chips Flavouring Machine | 1.12kw/380v/50Hz | 2800x850x2200mm |

| 14 | Potato Chips Packing Machine | 4.745kw/380v/50Hz | 1320*920*1392mm |