Temperature is an important factor for maintaining postharvest quality of vegetables and greatly influences the rate of deterioration.

Some of the processes associated with deterioration, like respiration, increase with an increase in temperature. For each 10 C increase in temperature, the rate of chemical reactions increases 2-3 times.

Lowering the temperature of vegetables decreases their rate of deterioration, reducing the respiration, extending their shelf-life. There are researchers reported an extension of shelf life of 2.5 days at 12 C for head lettuce, which were cooled for 20 min, sealed in polypropylene film and stored for a week at 2 C.

Precooling involves the rapid removal of field heat after harvest. Vacuum cooling is an ideal way to cool specific fresh produce, such as leafy vegetables and flowers, quickly.

A general vacuum precooling machine consists of a vacuum chamber, a vacuum pump system, refrigerating unit that includes an evaporator (water catcher), a compressor, a condenser and an expansion valve, automatic operation control system. These components work together to achieve optimum and efficient vacuum cooling results.

Vacuum Cooler Chamber

The vacuum chamber is a pressure vessel to hold the product desired to be cooled.

According to the precooling process scale, the vacuum tank is cylindrical or cuboid structure, which is made of food grade stainless steel and steel frame.

In order to create efficient insulation, the cooling cabinet was covered with thermal insulation material.

The door can be moved in the horizontal direction or rotated along the vertical axis direction, and built-in silicone rubber sealing strip to obtain good sealing performance.

Equipped with a drainage and cleaning system ensures internal sanitation.

Vacuum Cooler Vacuum System

The reduction in temperature via vacuum cooling is generated by partial evaporation of moisture directly from the product. Vacuum is drawn to the desire level by the vacuum pump. Therefore, vacuum pump plays an essential role in a vacuum precooling system.

The vacuum pump performance, both evacuation rate and ultimate vacuum, determines how long the desired process vacuum take place, thereby significantly affecting the pre-cooling time.

Rotary vane pump is generally applicate.

Nowadays, as the volume of batch vacuum cooling process increases, Roots and Rotary vane vacuum pump unit is recommended.

Vacuum Cooler Water Catcher and Refrigeration System

In the cooling process, there will be a lot of vapor which need vacuum pump evacuate. If few vapors enter into the rotary vane pump cavity, this will cause emulsification of the vacuum pump lubricating oil, which affect the ultimate vacuum and may not even work properly.

On the other hand, under processing vacuum, the evaporated vapor is of large volume, the requirement of vacuum pumping speed will greatly increase. It should not be directly extracted by vacuum pump.

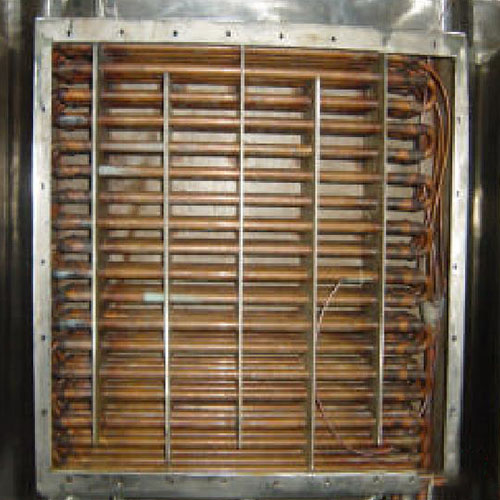

The evaporator, one component of refrigerating unit plays a key role in the good operation of the vacuum pump. It is also known as a water catcher. The vapors will undergo the cooling coil and condensate, follows drainage.

The air-cooled condenser and piston compressor refrigeration unit provides the vapor trapping kinetics for the water catcher. The low-temperature cold medium is generated by the refrigeration unit, generates a low-temperature on the surface of the cooling coil to condensate the vapor from cooled products.

Vacuum Cooler Automatic control system

Once fresh vegetables or other cooked foods loaded the vacuum cooling systems starts to evacuate the air from the vacuum chamber. The vacuum cooling process starts. All cooling processes are controlled by PLC, includes Touchscreen Human to Machine Interface Screens, complete control packages with record keeping of vacuum cooler performance.

Vacuum Cooler Applications

Vacuum cooling is a pre-cooling technology for rapid evaporation of water under vacuum, especially suitable for the cooling of vegetables, such as lettuces, leafy greens, cabbage, oriental vegetables.

Vacuum cooling has also been applied to the cooked fast food, Stir-fried dishes, rice, high-speed rail lunch, aviation meals, mixed fast food, grilled meat, noodles, various fillings, etc.

Vacuum pre-cooling is a kind that can keep the freshness of the picked flowers better method.