The frozen French fries industry has transformed dramatically over the past few decades. Consumer demand for consistent taste, texture, and quality has pushed manufacturers to adopt advanced equipment. Today’s Frozen French Fries Processing Machines integrate cutting-edge technology that enhances productivity, ensures food safety, and reduces costs. This article highlights the key features that define modern processing equipment and why they matter for food manufacturers.

Evolution of Potato Processing Technlogy

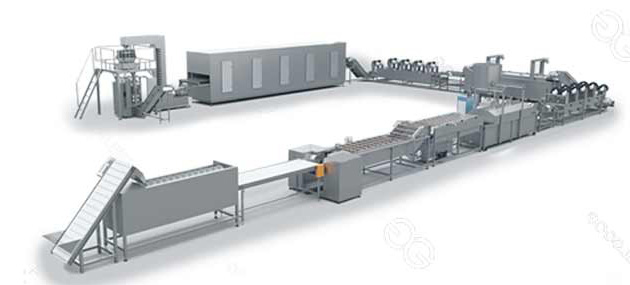

In the past, French fries were produced manually or with basic machines that required heavy labor. While these methods could produce fries, they lacked consistency and efficiency. Modern potato processing equipment solves these problems through automation, precision control, and improved hygiene standards. As a result, large-scale factories can process several tons of potatoes per hour while maintaining uniform quality.

Essential Features of Modern Processing Lines

1. Advanced Cutting Technology

Uniformity in French fries is critical for frying and freezing. Modern processing lines use hydro cutters or industrial slicers with high-speed water jets and stainless-steel blades. These machines ensure precise cutting, reduce waste, and minimize damage to potato strips.

2. Efficient Blanching Systems

Blanching is essential to preserve color, texture, and flavor. New blanching machines use controlled temperature and timing to deactivate enzymes while conserving energy. Some systems recycle water and heat, making them more eco-friendly.

3. Industrial Fryers with Oil Management

Frying is one of the most energy-intensive stages in production. Today’s fryers are equipped with automatic oil filtration and circulation systems, which extend oil life and maintain consistent frying conditions. This results in better product quality and reduced operating costs.

4. IQF Freezing Technology

Freezing technology has advanced significantly. IQF (Individual Quick Freezer) systems rapidly freeze fries, preventing them from sticking together and locking in freshness. These freezers also feature energy-efficient compressors and airflow designs that reduce operational expenses.

5. Hygienic Design and Food Safety

Modern Frozen French Fries Processing Machines are built with stainless steel and designed for easy cleaning. CIP (clean-in-place) systems and smooth surfaces eliminate contamination risks. Compliance with international food safety standards such as HACCP and CE is now standard.

Benefits of Advanced Equipment

– Improved Productivity: Automation reduces labor costs and allows for round-the-clock operation. A well-designed line can process up to 5,000 kg of potatoes per hour.

– Consistent Quality: From cutting to freezing, each stage is precisely controlled, ensuring uniform fries that meet customer expectations every time.

– Sustainability and Energy Efficiency: New designs focus on water recycling, heat recovery, and oil management, helping manufacturers lower their environmental footprint.

– Cost Savings: Although advanced equipment requires investment, the long-term benefits include reduced waste, energy savings, and higher yield.

How to Select the Right Machines

When investing in Frozen French Fries Processing Machines, manufacturers should evaluate:

– Production scale: Small vs. large capacity lines

– Automation level: Semi-automatic or fully automatic

– Energy efficiency: Features like oil filtration and water recycling

– Supplier support: Installation, training, and after-sales service

Conclusion

Modern Frozen French Fries Processing Machines are more than just tools; they are the backbone of efficient and profitable frozen fries production. With features like advanced cutting systems, energy-saving fryers, IQF freezers, and hygienic designs, today’s equipment ensures consistent quality and long-term savings. For food manufacturers looking to stay competitive, upgrading to advanced potato processing technology is a smart investment.

Interested in exploring modern frozen fries processing solutions? Contact us to learn more about equipment options tailored to your production needs.