Frozen French fries are one of the most popular convenience foods worldwide. From fast-food chains to retail supermarkets, demand for high-quality frozen fries continues to grow. To meet this demand, food factories rely on Frozen French Fries Processing Machines, which automate and standardize production. This article provides an overview of these machines, their working process, and why they are essential for modern food manufacturing.

The Growing Demand for Frozen French Fries

According to market studies, global consumption of frozen French fries is increasing steadily, driven by urbanization, quick-service restaurants, and changing lifestyles. For producers, this means investing in efficient potato processing equipment to deliver consistent taste, texture, and safety.

What Are Frozen French Fries Processing Machines?

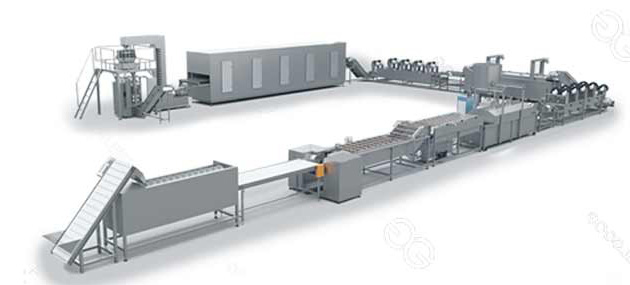

Frozen French Fries Processing Machines refer to a complete line of industrial equipment designed to transform raw potatoes into ready-to-cook frozen fries. These machines integrate multiple stages of production, ensuring hygiene, efficiency, and cost-effectiveness. A typical line includes washing, peeling, cutting, blanching, frying, freezing, and packaging units.

Key Stages in Frozen French Fries Production

1. Washing and Peeling

Freshly harvested potatoes often contain soil and debris. Industrial washing machines clean them thoroughly. Steam or abrasive peelers then remove the skins, preparing the potatoes for cutting.

2. Cutting into Strips

A hydro cutter or industrial potato slicer ensures uniform strip size, which is critical for consistent frying and freezing results.

3. Blanching

The strips are blanched in hot water or steam. This step deactivates enzymes, improves texture, and enhances the fries’ final color.

4. Drying and Frying

After blanching, surface water is removed by air dryers. The fries then enter an industrial fryer, where partial frying gives them their golden appearance and crispness.

5. Freezing

The fries are quickly frozen using an IQF (Individual Quick Freezer). Rapid freezing preserves freshness, prevents clumping, and extends shelf life.

6. Packaging

Finally, the frozen fries are automatically weighed, packed, and sealed for distribution.

Why Automation Matters

Modern Frozen French Fries Processing Machines are fully automated, reducing reliance on manual labor. Automation provides several benefits:

* Consistency: Every batch of fries maintains the same quality and size.

* Efficiency: High-capacity lines can process several tons of potatoes per hour.

* Food Safety: Stainless steel design and CIP (clean-in-place) systems ensure hygiene compliance.

* Cost Reduction: Less waste and lower labor requirements improve profit margins.

Choosing the Right Processing Line

Not all production facilities require the same setup. Small factories may choose semi-automatic equipment, while large-scale plants often invest in fully automated lines. Key factors to consider include:

* Production capacity (from 500 kg/h to 5,000 kg/h)

* Energy efficiency and water-saving features

* Compliance with international food safety standards

* Supplier reputation and after-sales service

Conclusion

The frozen fries industry is highly competitive, and the right equipment makes all the difference. Frozen French Fries Processing Machines enable manufacturers to produce uniform, high-quality fries while maximizing efficiency and profitability. As demand continues to rise, investing in advanced potato processing equipment is not only a necessity but also a long-term growth strategy.

Looking to set up or upgrade your frozen fries production line? Contact our team to explore the best solutions tailored to your factory needs.