Air blast fluidized bed freezer | iqf fluidized freezer

Air blast fluidized bed freezer | iqf fluidized freezer

Short Description:

Fluidization frozen is an ideal way to achieve the IQF (Individually Quick Freezing), which is suitable for freezing the flakes, lumps, strip and granular vegetables with rapid freezing speed.

Send Query Download PDFFluidized Quick-Freezer Features

Fluidization frozen is an ideal way to achieve the IQF (Individually Quick Freezing), which is suitable for freezing the flakes, lumps, strip and granular vegetables with rapid freezing speed.

Fluidization, that is, the material forms a similar boiling state by a low-temperature air which is blow from the bottom up, like the movement of the fluid, and in the movement is quickly frozen.

Technical Data

Standard scale of fluidized bed quick freezer includes 100kg/hr,200kg/hr, 300kg/hr,500kg/hr,800kg/hr, 1000kg/hr, 1500kg/hr, 2000kg/hr,2500kg/hr and 3000kg/hr.

Special scale is available to be customized.

An example technical data of 500kg / hr IQF fluidized quick freezer is as follows,

|

No. |

Item |

|

|

1 |

Specification |

LSD-500 Fluidized Quick-Freezer |

|

2 |

Normal Freezing Capacity |

500Kg/h |

|

3 |

Non-frozen Products |

Bulk, without any package |

|

4 |

Freeze Method |

Blast freezing |

|

5 |

Air Supply Mode |

Blow up from the lower surface |

|

6 |

Non-frozen Products Temperature |

≤15℃ |

|

7 |

Frozen Products Temperature |

-18℃,Central temperature |

|

8 |

Freezing Time |

8-20min |

|

9 |

Freezing Temperature in library |

-35℃ |

|

10 |

Defrosting method |

Water Defrosting |

|

11 |

Freezer Library Body Length |

6000mm |

Working Condition

|

No. |

Item |

Technical Data |

|

|

1 |

Electricity |

Power |

34KW |

|

Electricity |

380V/50HZ/3P |

||

|

2 |

Cold Source |

Evaporation / Condensation Temperature |

-42℃/+35℃ |

|

Cold Consumption |

96KW |

||

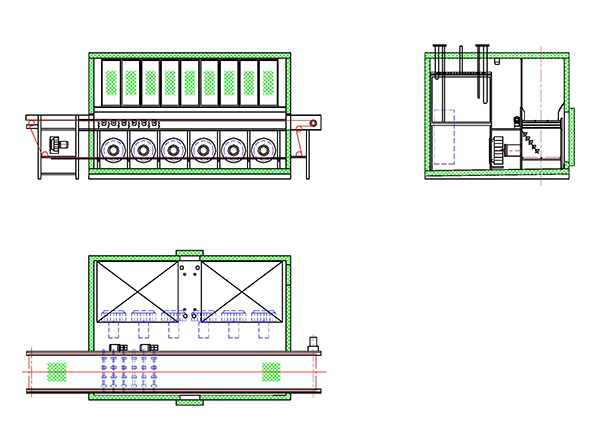

Main Parts Description

1. Support frame

The freezer library body is hanging with a support frame; it is easy to wash the ground.

2. Freezer library body and door

Freezer library body is made of duplex stainless steel sheet with polyurethane in the middle, it has a perfect thermal insulation performance.

Air cap is equipped in the feed inlet; cold will never be loss, so energy is saved.

1 pcs inspection door and an aisle are to make cleaning and maintenance easily.

3. Water collector and drainage

Water collector is in the whole bottom of libraries, all washing and defrosting water will not leak.

4. Mesh belt and driving gearbox

ST.ST Mesh meets the HACCP request, it runs smoothly due to some support tracks under mesh, chains on both side and reasonable tensioner, un-frozen fries are able to be put on mesh directly.

To ensure the feeding fries keeping loose without mutual adhesion, a blower and some pulse vibrating device in the front of mesh are designed.

Mesh belt is driven with invertor for different frozen fruit and vegetable request.

5. Air supplying and Fan

The air supply system provides a large amount of cold air flow evenly, also set the air deflector to effectively reduce the loss of kinetic & potential energy, completely cold air is around on the un-frozen fruits and vegetables, it is available to have quick freeze in the most short time.

Axial flow fan of low noise and high efficiency can run very well for a long service time in low temperature status. Also, maintenance is easy due to evaporator and fan set up separately.

Aluminium finned tube evaporator of high thermal efficiency is able to run for a long service time in low temperature with less frost formation and defrosting time.

7. Operation panel

Mesh belt is driven with invertor. 2 sets waterproof temperature sensor are set up to accurately measure the temperature in the freezer.

Screw compressor with evaporating condensor or piston compressors for a small scale are optional.

Previous: Quick Freeze Machine, Flash Freezing Equipment

Next : Spiral Quick Freeze Machine | Vegetable Quick Freezer

Refer to: Frozen French Fries Making Machine

Back to: IQF, Individual Quick Freezer