The global demand for frozen French fries continues to grow, driven by fast-food chains, restaurants, and retail consumers seeking consistent quality and convenience. At the core of this booming industry are frozen fries processing machines, which enable manufacturers to transform fresh potatoes into high-quality, ready-to-cook frozen fries efficiently and at scale.

This article explores how frozen fries processing machines work, the complete production process, and how to choose the right equipment for a successful frozen fries factory.

What Are Frozen Fries Processing Machines?

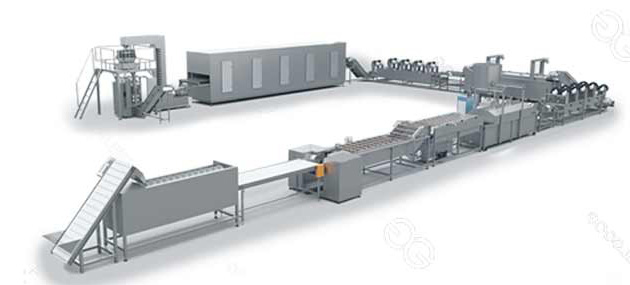

Frozen fries processing machines refer to a complete set of industrial equipment designed to process raw potatoes into frozen French fries. These machines are engineered to ensure uniform cutting, controlled cooking, rapid freezing, and food safety compliance throughout the production line.

A standard frozen fries processing line integrates mechanical, thermal, and refrigeration systems to achieve high output, consistent product quality, and low operational costs.

Complete Frozen Fries Processing Flow

A professional frozen fries production line typically includes the following stages:

1. Potato Washing and Peeling

Fresh potatoes are first cleaned to remove soil and impurities. Industrial washing and peeling machines use abrasion or steam peeling methods to achieve high peeling efficiency while minimizing raw material loss.

2. Cutting and Sizing

After peeling, potatoes are cut into uniform strips using high-speed cutting machines. Accurate cutting is critical, as consistent fry size ensures even blanching, frying, and freezing.

3. Washing and Blanching

Cut fries are washed again to remove excess starch, then blanched in hot water. Blanching stabilizes color, improves texture, and reduces enzymatic activity, preparing the fries for further processing.

4. Dewatering and Drying

Excess surface moisture is removed using vibrating dewatering machines or air dryers. Proper moisture control improves frying efficiency and reduces oil absorption.

5. Par-Frying

In most commercial applications, fries undergo par-frying in continuous industrial fryers. This step develops flavor, texture, and surface structure while maintaining a soft interior.

6. De-Oiling and Cooling

After frying, centrifugal de-oiling machines remove excess oil. Cooling conveyors then stabilize the product before freezing.

7. IQF Freezing

Individual Quick Freezing (IQF) is a critical step. IQF freezers rapidly freeze fries individually, preventing clumping and preserving texture, taste, and nutritional value.

8. Packaging and Cold Storage

Finally, frozen fries are weighed, packed, and transferred to cold storage, ready for distribution or export.

Key Advantages of Modern Frozen Fries Processing Machines

Investing in advanced frozen fries processing machines offers several advantages:

* High Production Efficiency: Continuous operation supports large-scale output, suitable for industrial factories.

* Consistent Product Quality: Automated control ensures uniform size, color, and texture.

* Energy and Cost Optimization: Modern systems are designed for reduced oil, water, and energy consumption.

* Food Safety Compliance: Stainless steel construction and hygienic design meet international food safety standards.

* Scalability: Processing lines can be customized for capacities ranging from small startups to large commercial plants.

How to Choose the Right Frozen Fries Processing Machines

When selecting frozen fries processing machines, consider the following factors:

1. Production Capacity

Define your target output (e.g., 500 kg/h, 2000 kg/h, or 5000 kg/h) to determine machine specifications.

2. Raw Material Quality

Potato variety and size affect peeling efficiency and yield. Machines should be adaptable to different raw materials.

3. Automation Level

Higher automation reduces labor costs and improves consistency but requires higher initial investment.

4. Energy and Utility Requirements

Evaluate electricity, water, steam, and refrigeration needs to ensure compatibility with your factory infrastructure.

5. After-Sales Support

Reliable technical support, spare parts availability, and installation guidance are essential for long-term operation.

Conclusion

Frozen fries processing machines are the backbone of a successful French fries manufacturing operation. From washing and cutting to IQF freezing and packaging, each stage plays a critical role in delivering consistent, high-quality frozen fries to the market.

By choosing the right equipment and designing a well-integrated production line, manufacturers can achieve higher productivity, better product quality, and long-term competitive advantages in the global frozen fries industry.