The global demand for frozen French fries continues to expand, creating opportunities for food manufacturers to enter or scale up in this profitable market. However, success depends heavily on selecting the right Frozen French Fries Processing Machines. With many equipment options available, understanding how to choose wisely can save costs, improve efficiency, and ensure consistent product quality. This guide outlines the key factors to consider when investing in a frozen fries production line.

Assess Your Production Capacity

The first step in choosing the right machines is determining your production scale.

– Small-scale operations (500–1,000 kg/h): Ideal for new businesses or local suppliers. Semi-automatic machines may be sufficient.

– Medium-scale operations (1,000–3,000 kg/h): Requires more automation to balance cost and efficiency.

– Large-scale factories (3,000–5,000+ kg/h): A fully automated processing line is essential to meet high-volume orders with consistent quality.

Your choice of capacity will directly affect both equipment cost and space requirements.

Semi-Automatic vs. Fully Automatic Lines

– Semi-automatic lines: Require more manual input, lower investment, and suit smaller businesses. However, they may struggle with consistency and labor efficiency.

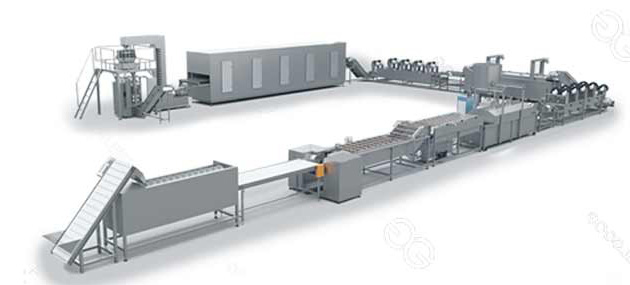

– Fully automatic lines: Handle washing, peeling, cutting, blanching, frying, freezing, and packaging with minimal human involvement. These are more expensive upfront but provide long-term savings through reduced labor and higher yield.

Key Features to Look For

When evaluating Frozen French Fries Processing Machines, pay attention to these features:

1. Cutting Precision

Hydro cutters and slicers that deliver uniform strips reduce waste and ensure consistent frying.

2. Frying and Oil Management

Industrial fryers with automatic oil filtration extend oil life, maintain flavor, and lower costs.

3. IQF Freezer Technology

An IQF (Individual Quick Freezer) preserves fries’ freshness, prevents clumping, and guarantees product quality during storage and transport.

4. Energy and Water Efficiency

Modern designs include recycling systems and heat recovery, lowering environmental impact and operating expenses.

5. Hygiene and Safety Compliance

Stainless steel construction, smooth surfaces, and CIP (clean-in-place) systems ensure compliance with HACCP, CE, and other food safety standards.

Cost Estimation and ROI

The cost of Frozen French Fries Processing Machines varies based on capacity, level of automation, and supplier reputation. While initial investment can be significant, manufacturers should calculate long-term ROI:

– Lower labor costs

– Reduced waste and energy use

– Higher production capacity

– Consistent quality leading to customer trust and repeat orders

Supplier Selection Matters

Choosing a reliable supplier is as important as selecting the machines themselves. Consider:

– Experience and expertise in potato processing equipment

– Installation and training support for your staff

– After-sales service and spare parts availability

– Customer references and case studies that prove performance

A trustworthy supplier ensures your production line runs smoothly and adapts to future needs.

Conclusion

Investing in the right Frozen French Fries Processing Machines is a strategic decision that shapes your factory’s productivity, cost efficiency, and market competitiveness. By evaluating production capacity, automation levels, key features, and supplier reliability, manufacturers can secure long-term growth in the frozen French fries industry.

Ready to select the ideal equipment for your factory? Contact us today for tailored solutions that meet your production goals and budget