Learn more about automatic thermoforming vacuum packaging machine

Learn more about Automatic Thermoforming Vacuum Packaging Machine

Post Time: 10 August 2021

The increased consumption of food requiring thermoformed packaging implies that the packaging industry demands customized solutions in terms of shapes and sizes to make each packaging unique.

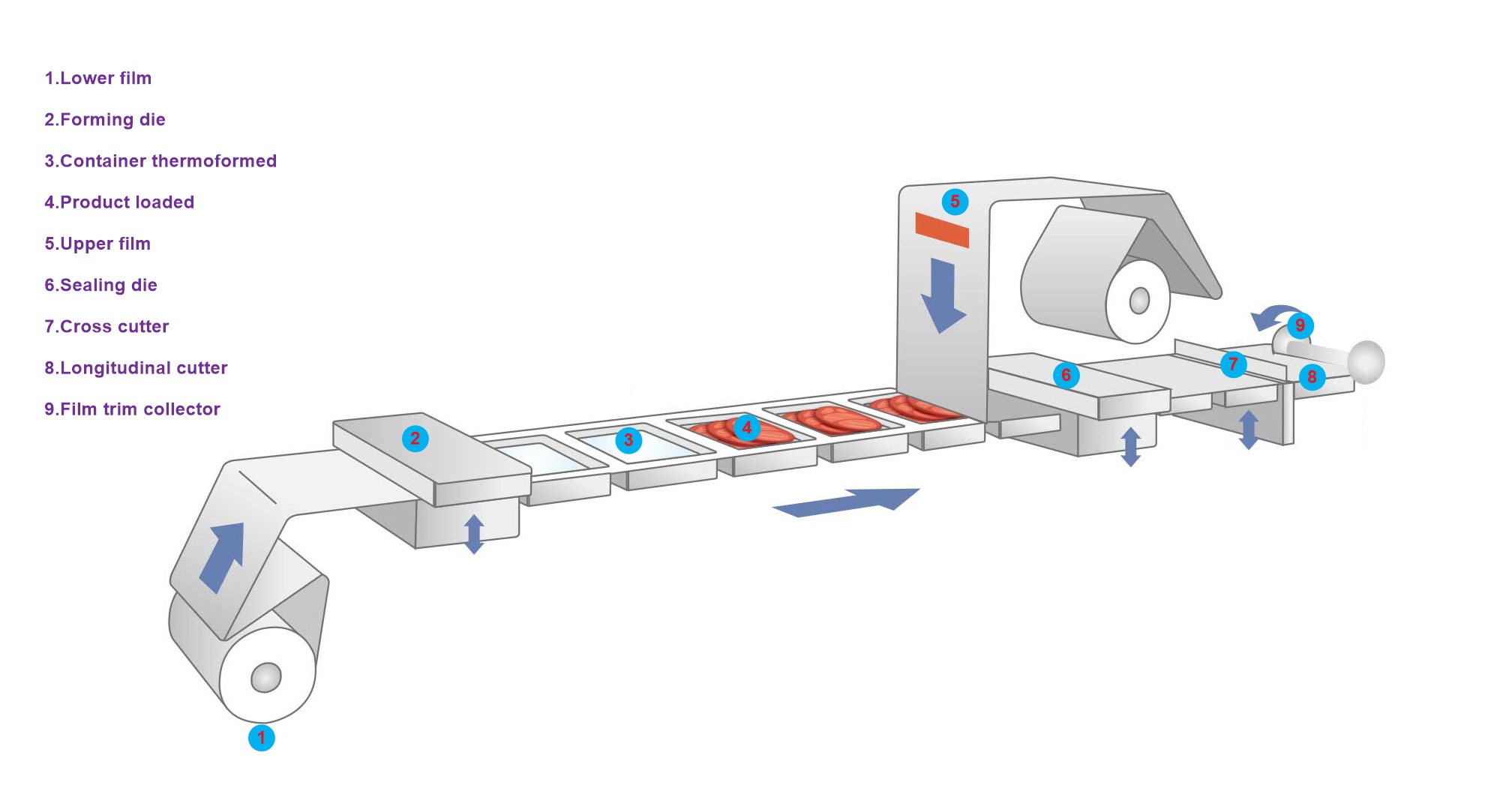

Thermoforming is a process of shaping flat thermoplastic sheet which includes two stages: softening the sheet by heating, followed by forming it in the mold cavity.

Thermoplastics which may be processed by the thermoforming method are:

Polypropylene (PP)

Polystyrene (PS)

Polyvinyl Chloride (PVC)

Low Density Polyethylene (LDPE)

High Density Polyethylene (HDPE)

Cellulose Acetate

Polymethylmethacrylate (PMMA)

Acrylonitrile-Butadiene-Styrene (ABS)

Thermoforming is widely used in the food packaging industry for manufacturing ice cream and margarine tubs, meat trays microwave containers, snack tubs sandwich packs etc.

Thermoforming is also used for manufacturing some pharmaceutical and electronic articles, small tools, fasteners, toys, boat hulls, blister and skin packs.

There are three Automatic Thermoforming Vacuum Packaging Machines, differing in the technique used for the forming stage: Vacuum Thermoforming , Pressure Thermoforming and Mechanical Thermoforming